Blog

Postings arise as time permits

and inspiration hits. Contact me

to request a special topic!

and inspiration hits. Contact me

to request a special topic!

|

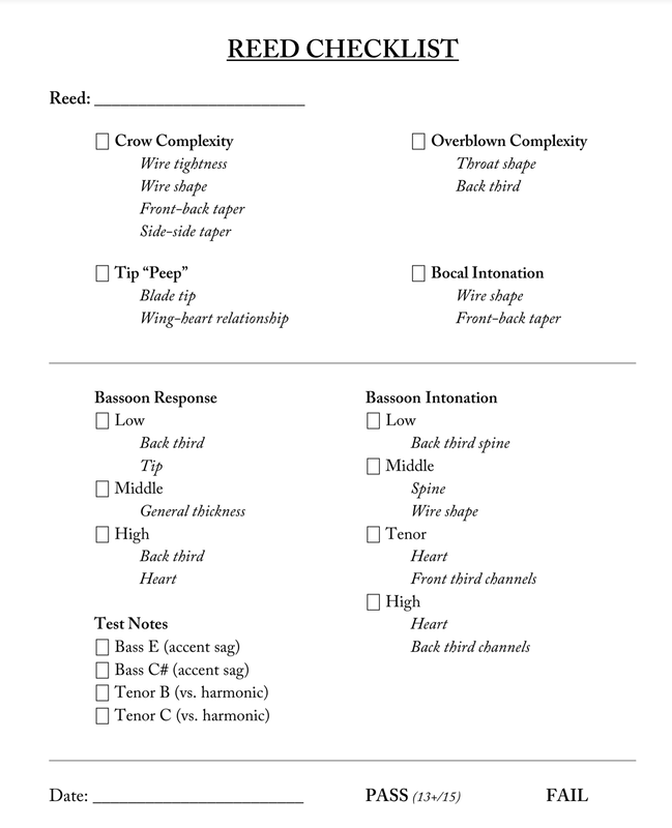

The verdict is in. I have officially put in all I am willing to input for a blank to become a functioning, stage ready reed. We all have our breaking point, and sometimes the product just isn't worth the resources. For your reference, here are a few examples of ones that are "worth it" in my mind - asymmetry that responds to a single scrape (image one) - and ones that aren't - persistent sideslipping (image two) and separated blades (image three). After another one or two sessions on each reed, adjusting according to my priorities: 1. RESPONSE 2. INTONATION 3. FLEXIBILITY 4. TONE I subjected each reed to my final checklist:  As you can see, 13/15 constitutes a passing score for me - generally suitable for other humans to hear. This is a B+ reed that is functional for the average situation. If a reed is destined for the stage, it must (MUST) score a 100% and sound beautiful. Here are the scores for the remaining blanks from each batch: Seam Aligned "Side" Wire Placement: - 13 - 10 - 8 - 7 - 2... yikes Standard Wire Placement: - 12 - 13 - 14 - and... two 15s! The bright blue wrapped, standard wire placement formed unicorn made its stage debut on my fall faculty recital, and its rainbow wrapped compatriot hopped in the mail to a student of mine to live on through the Iowa All State audition process. Hear one of theme in this teaser of the lovely second movement of Jenni Brandon 's Colored Stones, then check out the full recital through the link above! Much like some reeds being potential products that are not worth the process, I find myself reflecting on methods in the same manner, and with this set of cane, in these circumstances, for these purposes I think I will be leaving my formation process just as it is. ... until the next experiment comes along.

1 Comment

After an exceptionally long covid-driven "curing period," nine* of the original blanks made to compare seam aligned wires with traditional top-bottom wire placement have made it to my practice box, and the results are fascinating. *RIP bright blue seam aligned, a hapless victim of knocking my phone off the filing cabinet. A truly senseless crime. In the interest of full disclosure, I opened all of these reeds early in the Pandemic Blankapalooza, played all of them for 30-45 minutes, then stuffed them in a box and moved them a mile into the air with my relocation from Iowa to Colorado. The good news is that all underwent the same change. The bad news is that results are also at least partially the result of clipped blank babies moving to altitude. After almost three months of timeout, all underwent my second scrape process, which looks a little something like this: After this, the blanks sat for another couple of days, each receiving a scale or two play time to help navigate last weeks snow (!!) and get us back to something that looks like the end of summer in terms of both heat and humidity. Last night, each received a basic balancing scrape based on visual assessment and crow. Then came this morning... Traditional Top-Bottom Wire Twists Experimental Seam-Aligned Wire Twists Pull yourself together, side wires. Look at that asymmetry! Then I played them, standard three octave C Major with triads:

While a bit stiffer than I am accustomed to with sea level fresh clips and a reasonable, non-covid amount of time between first and second scrapes, the traditional twist reeds felt predictable and fairly consistent across registers, and you can hear the similarity between options. The seam aligned wire experiments, though, varied wildly. As I anticipated from the warped apertures, they felt awfully stuffy and limited, though the wider throat, as pictured in the original post, kept the pitch very low - definitely far too low for poor Number Two of the pack. But was the collapse all in my head? The seam alignment *should* keep things open enough for higher air volume, right? Was the volume at the sacrifice of structure? To the measurements once more:

Indeed, not all in my head. The sensitivity on the lower end of the spectrum will come with final tip finishing, so I am not concerned with that. What's up with that collapsing on the upper end for all the side wires, though? Certainly not what I would hope for, but not outside the realm of adjustability. These wire placements simply prioritized opposite ends of my stability-flexibility spectrum: !!So, the plan...

For the Traditional Top-Bottom Wire Twists:

For the Experimental Side Wire Twists:

Part Four the Final coming soon! After much ado, I have returned to the blogosphere to document a recent reed making experiment inspired by my friends in Blankapalooza 2020 and a series of photographs by my former sectionmate and bassoon whiz, Jacob Darrow. If successful, a very minor change in blank formation could greatly reduce or (*gasp?*) potentially eliminate the need for blade imbalance corrections after the initial scrape. Too good to be true? Let's see. The Hypothesis: Uneven blade pressure, even slight, causes one blade to be more peaked than the other, which can lead to a host of issues -

The double blades of bassoon reeds are acted upon by unequal forces and torques based on the method by which we assemble blanks - first and second wires twisted in opposite directions, pulling one blade inward then counteracting with an opposing pull. This is the classic wire placement. But what if the blades were acted upon with force instead to the sides? In theory, this would create balancing forces in a lateral "shifting" manner rather than directly upon the spine in a "squishing" manner. What if we eliminated the doing and undoing of uneven blade pressure during formation? I thus hypothesized that placing wire twists along the seam of the reed as opposed to the spine can eliminate chronic side slipping, reduce asymmetry, and increase air volume through the throat. PART ONE - FORMING The Method: For this experiment, I used 14 pieces of cane from the same tube batch order; gouged, shaped, and profiled with the same instruments on the same day; dried and soaked matching times in the same humidor and water container, respectively; and formed in the same one hour sitting with the same tools and measurements. For my formation process, check out the "Resources" and "Documents" tabs in the menu above. I was surprised in the initial formation that the seam-aligned approach saved me time, roughly four seconds per blank. This makes sense in hindsight, as it takes an extra tug or two for the slack in the standard placement method to make sure the full wire is flush with the newly rounded tube, rather than when pulling parallel to the oblong throat. This seems small, but a few seconds per blank adds up before long.

The Observations: Forming with my traditional method felt more comfortable but, as seen above, was a hair slower. As you take a look through the comparison photos below, you'll see a few observations: 1. Contrary to my hypothesis, it was easier to over-tighten the seam-aligned wires. I affectionately call these my muffin top reeds. 2. My hypothesis appears incorrect yet again in the constriction of the throat. The extra tug to round the tube fully via the second wire during forming appears to have consistently maintained the inner volume of the throat that fits so well with my beefy 201 and general approach to all things musical. 3. Since I like the vibrant and live-wire experience of a brand new reed, I have no qualms about opening them immediately. You can see a continuation of the throat volume into a wider tip aperture. Score one for the seam-aligned, though, the blanks are more symmetrical across all four tip quadrants than my wild child standard tips. This is the only part of my hypothesis projecting accuracy. PART TWO - SCRAPING The Method: All 14 blanks were dried overnight again, per my usual process, then I put in the thumbnail and tip, blending uniformly through the channels across the full batch. Regardless of experimentation, I complete identical first scrapes to all reeds, with the goal to be to define the front third of the reed and scrape the tip to within 0.1mm of my final goal thickness. With the profiler settings I use, this requires only a single scrape session and involves taking off less than 50% of the profiled tip thickness. After the "stock" tip and blending, I rested the blanks overnight in a humidor then gave what I referred to as a "good faith scrape" to tend to what each reed needed to fundamentally clear basic response and intonation variables before setting them aside to dedicate a specialized finishing scrape session to each. The Observations: All this began with a crow...

As you might imagine, the flatter shape of the seam-aligned wires yielded an initially low crow and easy response, while my first sounds on the standard-wired system sounded all too familiar. In conclusion, however, both crowed in the realm of acceptable. Sidebar - it is important for us to not allow either hope for a new method or comfort in an old one to guide our tests. Don't play better on the ones you want to sound good. This is true for reeds you wrap really pretty, too More on that later, I am sure, but the purpose of that note here is to acknowledge that I dig the idea of something new and immediately responsive helping both my students and myself, so I inserted a few "blind" crows, where I crowed the reed without looking at or touching the wires to have an expectation for their performance. Aside from poking myself on fresh wire clippings, nothing surprising happened, and they performed similarly down the rack and received the same tips. After two days' rest - happy weekend, everyone - I soaked and only made minor aperture adjustments to test the playability via a few stolen guitar waltzes, and what interesting surprises awaited me...

Yikes. The two racks now perform... opposite? The standard wire placement reeds have brightened and retained a large portion of their flexibility, and the seam-aligned reeds have completely seized. You can hear that both from the left column are bright, flat, and loud, the typical traits of a less aggressively tapered system that *should* have been set up moreso by the oblong second wires of the seam-aligned process. The right columned reeds are stuffy, sharp, and causing all sorts of neck veins to pop out as I play, which is not only glamorous but also, honestly, very unexpected. A twist! A cliffhanger! Perhaps all three facets of my hypothesis are wrong! Stay tuned for the next round, coming soon... PART THREE - FINISHING Thoughtful holiday gifts for bassoonists can be tricky! How do you best support your bassoon-crazed loved one and give them a gift they actually want? As much as I have a soft spot in my heart for gifts such as these... ... here is a quick shopping guide for items that your favorite bassoonist would be truly excited to receive. Happy shopping! On a budget? |

| Intellectual: Read the following ten books:

|

October 2020

September 2020

April 2020

November 2018

August 2018

September 2017

January 2016

August 2015

December 2014

September 2014

August 2014

May 2014

March 2014

January 2014

December 2013

November 2013

October 2013

September 2013

July 2013

June 2013

May 2013

March 2013

All

Anxiety

Auditions

Collaboration

Goal Setting

Lessons

Performance

Practice

Psychology